Square bale wrapper

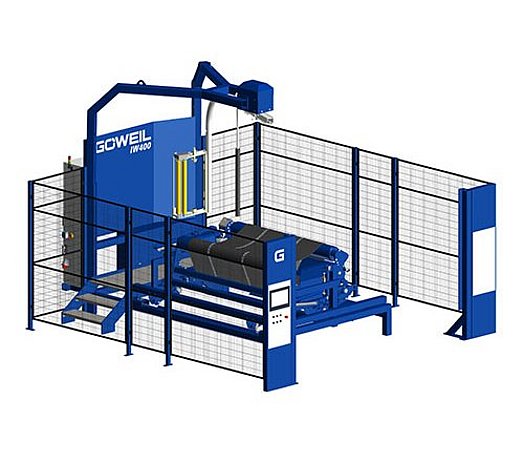

IW400 | Stationary wrapping machine

The IW400 stationary wrapping machine can be individually adapted - from the basic machine to the professional system.

Loading and wrapping of square bales is completely automatic with the PROFI program control.

Workflow

The IW400 wrapping machine is the ideal choice for wrapping square bales. It is used to film-wrap bales produced by industrial balers, so that bales can be optimally stored. It provides an ideal temporary storage solution for daily waste, especially during plant maintenance periods. Thanks to the modular system, the industrial wrapper can be perfectly adapted to every customer requirement.

Highlights

IW400 Wrapping machine

➡ Wrapping table with bale conveyor belt

The roller tubes arranged on both sides are connected to each other by control rods. This results in forced control which, in conjunction with the conveyor belt, produces a clamping effect on the bale. This means that the wrapping table ensures reliable bale guidance, especially with rectangular bale dimensions. Once the wrapping process is complete, the conveyor belt of the wrapping table is tensioned and the bale is transferred to the conveyor belt.

➡ Wrapping arm with film pre-stretcher

Both the single and twin wrapping arms are equipped with 750 mm film pre-stretchers and film cutters. The wrapping units also have a film monitoring system that switches off the wrapping process if the film tears or comes to an end. The optional twin wrapping arm with single-film mode also finishes wrapping bales with one roll of film. GÖWEIL's long-term tried and tested wrapping technology guarantees clean bale wrapping.

➡ Platform for film change

A fixed platform is installed behind the wrapping unit for changing the film, allowing the wrapping film to be changed at a comfortable working height. A second platform is included with the optional twin wrapping arm. This makes it easier to change film on the second wrapping arm and also serves as a transfer aid for the RFB60 remnant conveyor belt auxiliary module.

➡ Main control cabinet and hydraulic oil supply

The central main control cabinet with integrated control system and rotating field monitoring is integrated in the base machine and gives users the option of expanding the system with all optional modules. The central hydraulic oil supply is provided by a hydraulic unit with a 30 l tank including tank heating and level monitoring and has an oil cooling system in the return line. Pressure and return flow filters are also installed as standard. Connections for the automatic bale feeding are provided.

➡ Safety fence

The safety fence can vary depending on the equipment of the wrapping unit and the customer's local conditions and is offered in meters. Optional access doors can also be integrated, complete with door locking. This makes changing the film easier, and also simplifies maintenance and servicing work. A light grid for the bale loading and unloading zone can be installed as a safety precaution if required.

➡ Program control

The entire machine or system is controlled fully automatically via the program control developed specifically for the required program sequences. Navigation, work sequences and maintenance processes are displayed simply and clearly on a graphic terminal. The operating terminal can be installed at several positions around the system.

Basic Model

- Wrapping table with bale conveyor belt

- Feed cut-off

- Single wrapping arm with film pre-stretcher for 750 mm

- Film cutter

- Film monitoring

Power supply 32A (400V)

with rotating field monitoring

- Optionally with doors

- Billing in running meters

Technical Data // Basic Model

| Dimensions LxWxH | 5,500 x 4,700 x 3,700 mm |

| Drive output | 400V / 32A |

| Bale size | 80 x 80 cm to 120 x 400 cm |

| Bale weight | max. 1,500 kg |

Additional Equipment

with weighing table, weighing terminal, and label printer

- with single-film mode and second platform for film change

- only with side loading of the IW400

IW400 Auxiliary Modules

only with side loading of the IW400

RFB60 remnant conveyor belt

A 6 m long remnant conveyor belt can be optionally positioned beneath the wrapping table. This transports remnants that come loose from the bale during bale transfer or the wrapping process out of the fenced system, thereby simplifying cleaning work and enabling baled material remnants to be returned to the baling process.

BFB42 bale conveyor belt

Up to two 4.2 m long bale conveyor belts can be adapted for simple and faster loading and unloading of the wrapping unit, making it possible to load and unload the conveyor belts during the wrapping process. This works both directly with a forklift and with the AB400 (automatic bale feeding; see point 7).

BFB15 bale conveyor belt

To speed up the process of loading and unloading bales, an additional 1.5 m long conveyor belt can be placed upstream of a BFB42 for the intermediate storage of bales that have already been wrapped.

AB400 Automatic bale feeding

The AB400 is an automatic bale feeding system that can take the bale directly from the waste compaction system. The unwrapped bale is then picked up by a bale manipulator and placed on a BFB42 bale conveyor belt for transport to the wrapping table.