Get to know GÖWEIL

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

Since 1988, GÖWEIL has epitomized excellence in the area of baling and wrapping technology thanks to a product selection of unsurpassed quality. All machines and equipment are designed, developed and produced exclusively at the company's location in Kirchschlag (Upper Austria).

As an exceptionally high portion of their products are exported, GÖWEIL machines have become renowned and are widely used throughout the world. When it comes to developing and manufacturing bale pressing and bale wrapping devices, GÖWEIL put its trust in its own planning department and its employee's long years of experience and know-how in product development and product manufacturing. All products made by GÖWEIL reflect the state of the art and are designed to fit the individual requirements of your specific applications.

The company has just under 250 employees; the success of the company is reflected in the constant growth.

Our values:

The following four values shape GÖWEIL's corporate culture:

Management

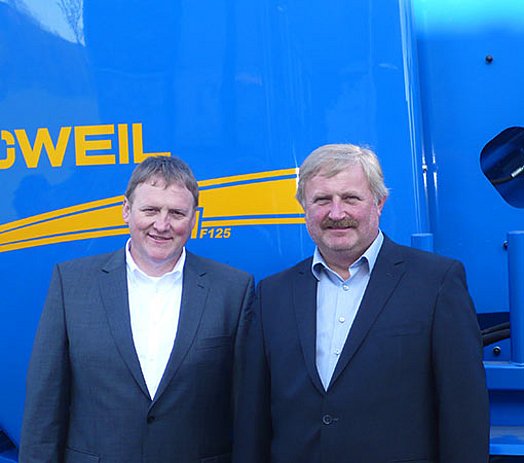

The company was founded by the trained master machinist Herbert Göweil. In the first year he developed the company's first wrapper. A milestone for the first wrapper was implementation of a rotating wrapping arm, which did not yet exist in this design. This was the foundation for today's success.

Over the last few decades, GÖWEIL has established itself worldwide as a specialist in the manufacturing of agricultural machinery and today it has also made a name for itself in the manufacturing of pressing and wrapping technology for industry.

Locations

GÖWEIL Headquarters

Kirchschlag bei Linz

The Göweil headquarters has been located in Kirchschlag near Linz / Upper Austria since the beginning.

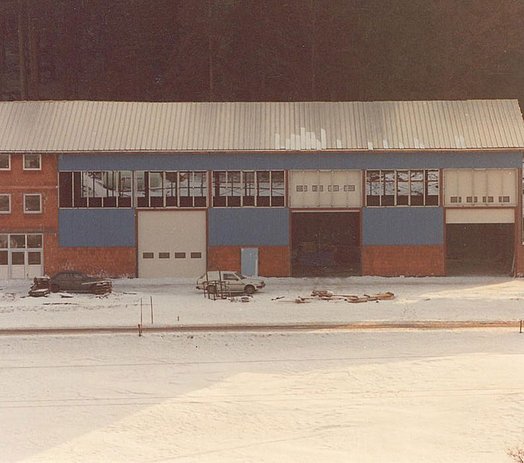

In 1991, the construction of the current building was started. Over the years, the site was gradually expanded until finally the entire area was exhausted.

Production Site

Rainbach im Mühlkreis

The second production site of GÖWEIL is located in the INKOBA area in Rainbach im Mühlkreis / Upper Austria. The building with a total area of 15,500 m² has a paint shop, assembly hall, shipping hall and office space.

Since no expansion was possible at the Göweil headquarters in Kirchschlag near Linz, this plant was built for the production of individual products.

Subsidiaries

GÖWEIL Switzerland AG

Since 2021, Göweil Switzerland AG functions as the general importer for Switzerland and Liechtenstein. The administrative premises as well as the workshop and storage area are located in Rohrbach in the canton of Bern.

Managing Director Bruno Bolliger has been with the Göweil brand in Switzerland since 2014 and took over as Managing Director of the newly founded company on September 1, 2021.

GÖWEIL BNL PGmbH

GÖWEIL BNL GmbH has been the general importer for Belgium, the Netherlands and Luxembourg since 2015. GÖWEIL products had already been successfully established in Belgium through a close partnership. The new location in St. Vith, which opened in 2023, offers modern administrative premises, a prestigious showroom, a well-equipped workshop and generous storage space.

Nicolas Krämer took over the management of GÖWEIL BNL on May 1, 2025 and has been responsible for the strategic and operational management of the company ever since.

History

Herbert Göweil founded the company Göweil as a fitter's shop and agricultural machinery business. Starting with three employees on the family farm vehicle bodies were produced and various contract work was carried out.

The first wrapper with a rotating wrapping arm was developed. However after the first field trials this machine was broken down into is basic parts and reworked. However, the second machine, named Siloboss, is still in use to this day.

The family garage then became too small, and this is why at today's headquarters in Kirchschlag, the new main building with workshops and office building were erected.

In addition to the silage technology, approximately 300 windrow turners were produced and sold. Since the trend towards round bale silage technology kept increasing, Herbert Göweil focused on this technology and stopped production of the windrow turner.

A paint shop was erected.

The first baler-wrapper combination was developed with a round baler from John Deere, and it won the silver medal at Agritechnica. This was a huge success for the aspiring company.

The company building was extended with a 500 m² production hall.

The subsidiary Göweil GmbH was founded in Huttwil / Switzerland by Fritz Zürcher and Herbert Göweil.

Development trials of a square baler named "Quako" were conducted.

The first maize combination was developed together with the Swiss company "Landtechnik Zollikofen". In this regard the Swiss company contributed the baler and Göweil contributed the wrapper combination.

Göweil reworked the "Maiskombi" from the previous year thus and Göweil's first LT-Master came into being.

The company site was extended with additional production halls and office space. To do this a 45,000 m³ excavation was necessary.

Presentation of the new corporate logo.

Due to the excellent order situation another annex of 2,400 m² production space and 3,500 m² storage space became necessary.

The company building was extended with additional office space and break areas, and an electronics workshop and storage area.

Göweil's first round baler, the G-1 F125 was officially presented. As part of this presentation open days were hosted and approx. 7,000 visitors participated.

Foundation of the subsidiary Göweil BNL in Belgium, by longstanding partner Josef Goffinet and Herbert Göweil.

With the purchase of business property in Rainbach im Mühlkreis the foundation was laid for a new, second location.

Groundbreaking ceremony for the new location in Rainbach im Mühlkreis

Establishment of GÖWEIL Switzerland AG - New general importer for Switzerland and Liechtenstein

The start in Rainbach was successful. After just under a year and a half of construction, we were able to start up production.

Awarded the title of Firefighter-Friendly Employer by the Federal Firefighters' Association.

Open house at the new plant in Rainbach im Mühlkreis attended by around 9,000 visitors

GÖWEIL BNL PGmbH moves into the newly constructed building in St. Vith / Belgium after a construction period of one year.

The small model in the Master series, the LT-Master F60, was presented for the first time at Agritechnica in Hanover.