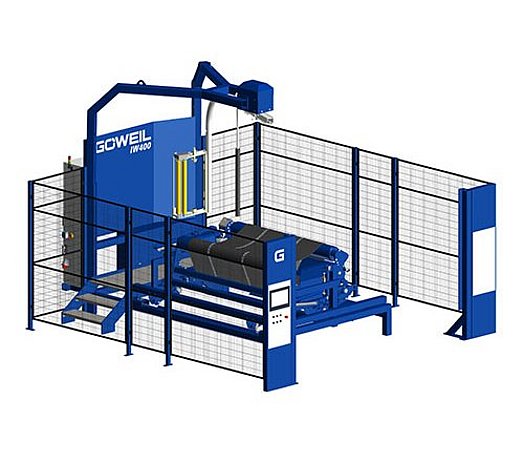

Pallet wrapper for turf and palletized goods

G1010 | Pallet wrapper

The G1010 pallet wrapper is the perfect device for transporting, wrapping and loading palletized goods. The machine is the best tool for packaging rolls of grass sod. The G1010 pallet wrapper's design has taken several clues from our tried-and-tested round bale wrapping technology. What is more, the G1010 pallet wrapper comes with a wide selection of loader attachments.

Highlights

Pickup and transport

With the G1010 pallet wrapper, you can transport, wrap and load full pallets, all with a single vehicle. The pallets are picked up with ordinary forks. During transport, the film cutting and wrapping system is folded up and out of the way. The tines can be inserted all the way under the pallet, until the pallet rests against the load backrest. As a result, the load is very close to the tractor. And thanks to the side-positioned upper frame section, the driver always has a clear view of the pallet.

Hydraulically actuated film stretching unit

Another standout feature is the hydraulically actuated film stretching unit. Moving 600 mm up and down during wrapping, the unit is capable of using a 750 mm film to fully wrap a pallet with a height of 1,350 mm.

Fully automatic program control PROFI

The wrapper is equipped with the program control PROFI. This control allows the operator to conveniently execute all work cycles and functions from the cab. All work steps can be performed manually and in fully automatic fashion.

Forks

The G1010 pallet wrapper is fitted with the standard ISO 3B mount for the forks. With its 1400 mm forks, picking up and transporting pallets is easy. Other available options are 2200 mm forks or telescoping tines (1300 mm long, extensible by 950 mm).

Hydraulic foldable film cutting and wrapping system

The hydraulically actuated film cutting and wrapping system folds down before wrapping starts. The pallet is lowered to the pallet stop, and wrapping can begin. After the last turn in the wrapping process, the system folds up, cuts the film off cleanly and secures it in place. The cutting and wrapping system folds up and out of the way to make pallet transport easier.

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

Basic model

(without attachment)

can also be operated in conjunction with vehicles without load sensing pump

For film widths between 500 mm and 750 mm (20” – 30”); the overlap can be adjusted as well

Height adjustment: 600 mm (2’)

The execution of all work cycles is fully automatic

Stops wrapping process if film tears or runs out

Technical data (basic model)

Weight (without fork tines): | 760 kg (1,675 lbs) |

Length (without fork tines): | 2,000 mm (6’ 6”) |

Width: | 1,400 mm (4’ 7”) |

Height: | 2,240 mm (7’ 4”) |

Maximum pallet size: | 1,350 x 1,350 mm (53” x 53”) |

Maximum pallet height: | 1,700 mm (67”) |

Oil requirement: | starting at 25 l/min. at max. 190 bar |

Pallet weight: | up to 2,000 kg (up to 4,400 lbs) |

Required connections

1 pressure connection and 1 depressurized return for the supply of the wrapper |

Load Sensing connection (required for LS mode only) |

3-pin power outlet for the electrical supply including direct supply line to the battery (cable cross-section 2x6 mm²) |

Possible attachments

| Euro-attachment |

| Merlo, Weidemann hydr., Kramer, Schäffer small, Faucheux, Giant |

| SMS, MX, Dieci/New Holland, JCB Compact Tool Carrier, Schäffer big, Claas Scorpion, Zettelmeyer 602, CAT 907H / Liebherr L507, Liebherr L514, Skid Steer, Merlo ZM3, Faresin, CAT TH 407 C |

| JCB Q-Fit, Atlas, Volvo BM, Fendt Cargo T955/Sennebogen, Forklift-attachment ISO II, Manitou, Cat. II and Cat. III three-point linkage |

| Amkodor, Bobcat |

Other attachments |

| Overview attachments |

Additional equipment

Required connection: 3-pin power outlet for the electrical supply of the hand-held terminal

(12V/10A)

For a better overview in the area of the fork tines and film cutter

Required connection: 12 volt hybrid connector DIN ISO 4165

Especially for operation with wheel loader or telescopic loader