Round Bale Unroller | RBA

The RBA round bale unroller is exceptionally well-suited for opening bales of silage, hay and straw and allows for particularly quick and clean fodder distribution without much effort.

The pulper is also optimally suited for short, long, cut or uncut fodder and even for tightly compressed bales.

Highlights

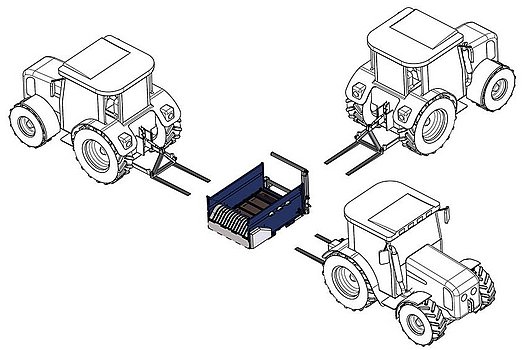

Hydraulic loading arm

The hydraulic loading arm picks the bales up in a snap. This eliminates the need for an additional vehicle. Mounting the loading arm on the other side only requires a few simple steps.

Electric drive

This drive makes it possible to use the round bale unroller as a stationary unit as well.

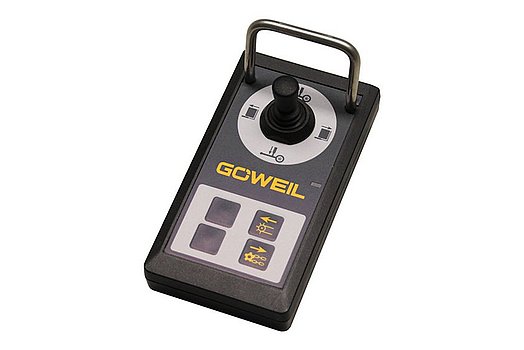

Radio remote control

A compact operating unit with radio control offers a convenient way to control the RBA both from the tractor and from outside the tractor. The associated control device is mounted on the RBA.

For operation with a wheel loader or telescopic loader, a single-acting control device with free return, as well as a 12-volt connection are required.

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

Basic model

Technical data (basic model)

Basic device:

| Weight: | 520 kg (1,150 lbs) |

| Length: | 1,600 mm (5' 3") |

| Width: | 2,100 mm (6' 11") |

| Height | 1,100 mm (3' 7") |

| Bale weight: | up to 1,000 kg (2,200 lbs) |

Device with loading arm and stacker collet:

| Weight: | 760 kg (1,675 lbs) |

| Length: | 1,800 mm (5' 11") |

| Width: | 2,230 mm (7' 4") |

| Height: | 1,477 mm (4' 10") |

Shortened version:

The width is reduced about 300 mm (12") |

Required connections

| 1 pressure connection and 1 depressurized return |

Possible attachments

Adapter Weiste triangle Cat. II |

Other mounting options available on request |

Additional equipment

With 2 load cylinders and 1 telescopic cylinder (loading arm can be reattached on the opposite side with a few hand movements). Double-acting hydraulic control device required.

Fixture for evenly spreading straw

only in conjunction with spreader attachment

Composed of 4 kW electric motor with hydraulic pump, return filter and hydraulic oil tank as well as control device for scraper floor

Drawbar combined with drawbar eye D40 and tractor linkage drawbar, mechanical support for bale pick-up

Double steering wheels (for operation in conjunction with smaller tractors), only in conjunction with three-point linkage, top link bolt must be attached with a chain, not suitable for articulated steering tractors!

For adjusting the speed of the scraper floor and of the pick-up

Solenoid valve, radio remote control for the load arm and scraper floor functions.

Solenoid valve, radio remote control for the load arm, lift axle, and scraper floor functions.

Only in combination with quantity control valve RBA