Stationary round bale wrapper with diesel engine

G3010 Profi | Round bale wrapper

The G3010 Profi round bale wrapper with diesel engine is the perfect stationary machine for the demanding use of contractors. All operations are fully automatic, allowing the operator to fully concentrate on bale handling. This saves time and costs—the output per hour is significantly increased!

Highlights

Design

The Series G30 wrappers are particularly characterized by their low working height. The robust and solid design and workmanship of the wrapper guarantee a long service life.

Wrapping arm with film pre-stretcher

The wrapping arm comes with a film pre-stretcher for 750 mm film rolls. The patented plastic rollers ensure uniform pre-stretching. This saves film and guarantees tightly wrapped and airtight bales. In addition, the rollers are not temperature sensitive. The quick-change system allows empty rolls to be replaced quickly and easily.

Rotating wrapping arm with stationary wrapping table

It is impossible for the bale to fall off with this system as there are no centrifugal forces acting on it. While the belts ensure continuous rotation of the bale, the two rotating bale guide rollers (optionally up to four) keep the bale in position. This guarantees uniform overlapping of the film. When bale deposit is performed, the wrapping table is tilted to the side and the bale is gently deposited next to the machine.

Film Cutter

The stainless steel cutting knife guarantees clean and precise cutting of the film. At the same time, the film is fixed by the cutting lever. Shortly after the start of the wrapping process, the standard float position ensures easy release of the wrapping film.

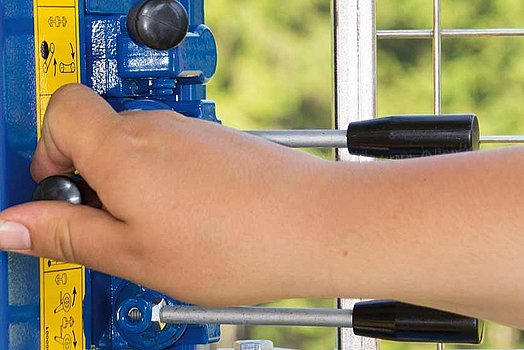

Control unit with hand lever

The control unit and the hand lever are helpful for maintenance and service work. All functions and processes can be performed directly on the machine. This means that the operator can simply leave the handset in the tractor cab.

Drawbar & axle

The hydraulically adjustable lift axle and articulated drawbar allow the G3010 Farmer and Profi machines to be pulled and parked in work position. The wrappers can be easily loaded with a transport fork due to their low height. A front loader is not required.

Film magazine

It is extremely important to have enough film on long workdays. With the G3010 Farmer, up to four rolls of film can be transported, and up to 16 with the G3010 Profi. The holders are located on the rear side of the wrapper at a comfortable working height.

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

Basic model

(without hydraulic oil) - WITH EU type-approval

- 17.5 kW diesel engine

- Water cooled

- Battery

- Electric starter

- Hours counter

- Return filter

- 44 l hydraulic oil tank

The execution of all work cycles is fully automatic

Technical data (basic model)

Weight: | 1,670 kg (3,680 lbs) |

Length: | 5,610 mm (18’ 5”) |

Width: | 2,410 mm (7’ 11”) |

Height: | 3,030 mm (10’) (with the lift axle extended) |

Bale diameter: | 0.90 – 1.60 m (36” - 63”) |

Oil requirement: | Self-sufficient oil supply |

| Bale weight: | up to 1,800 kg (up to 4,000 lbs) |

Required connections

| 7-pin power outlet for the entire lighting system (excluding work lights) |

| 3-pin power outlet for the electrical supply of the hand-held terminal (12V / 10A) |

Additional equipment

Width altered to 2,545 mm (8’ 5”), height altered to 3,090 mm (10’ 2”) (with lift axle extended)

Stops the wrapping process if film tears or runs out

maximum 2 items

Automatically switches to idle speed after the wrapping process or extended intervals

Country-specific equipment

without EU type-approval

without EU type-approval