Trailed round bale wrapper with twin wrapping arm

G5012 | Round bale wrapper

The trailed round bale wrapper with twin wrapping arm G5012 is furnished with a twin wrapping arm and a bale pick-up. This cuts the time that is necessary to wrap the bale in half! You will save time and money especially on long workdays. The G5012 is equipped with the STANDARD program control. Find out more about this trailed round bale wrapper with wrapping arm here.

Highlights

Design

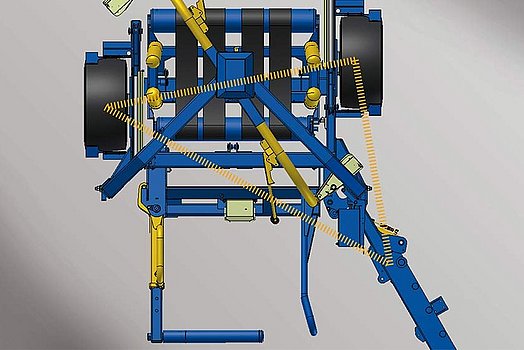

The robust construction and quality craftmanship of the wrapper guarantee an exceptionally long lifetime. Its compact and wide design makes this round bale wrapper extremely agile and perfectly suited for working on slopes. In addition, its low center of gravity allows for a level of maneuverability that is second to none. The standard 380/55-17AW tires ensure uniform weight distribution and are gentle on the soil.

Rotating wrapping arm with stationary wrapping table

This system reliably prevents the bale from falling off as it is not subjected to any kind of centrifugal forces. The conveyor belts and the four rotating bale guide rollers guarantee that the bale will continually move forward and, consequently, ensure a uniform overlap of the film. When it is time to drop the bales, the wrapping table is lowered all the way to the ground. This provides for a particularly gentle unloading of the bales.

Wrapping arm with film stretching unit

The film stretching unit is designed to accommodate 750 mm rolls of film. Three patented plastic rollers provide for perfectly uniform stretching. What is more, the rollers are not sensitive to temperature. This property helps save film and guarantees that the bales will be wrapped firmly and in an air-tight manner. The wrapping arm is available in two sizes – an added bonus is that the stretching units are height-adjustable. This ensures that the bales will always be wrapped perfectly around their own center. The quick-release system makes it possible to change empty rolls quickly and effortlessly.

Automatic film cutting and holding system

The stainless steel knife guarantees that the film will be cut cleanly and precisely. At the same time, the film is fixed in place by the cutter lever. Shortly after the wrapping process begins, the standard float position ensures that the film will unwind easily.

Axle

The machine is mounted on top of an offset axle. The work position has been shifted to the right, providing for perfect weight distribution.

The benefits:

- Perfect weight distribution especially during bale pick-up

- The wrapper can also be pulled by smaller tractors

- Excellent stability on slopes

Lever

The levers come in particularly handy during maintenance and service operations. They allow you to control all functions and processes directly at the machine.

The driver can easily leave the program control in the tractor cab when he, for example, needs to change the film.

Film storage

When working long days, you need to make sure that you have enough film. This wrapper allows you to carry along up to six rolls of film. The holders are mounted on the drawbar. This arrangement makes it possible to load and unload the film rolls with ease at a comfortable working height.

Pivoting drawbar

The hydraulically adjustable pivoting drawbar allows you to operate the machine with perfect ease – bale pick-up from the front in the baler's direction of travel, bale deposit towards the rear. The standard lower linkage link is responsible for the wrapper's outstanding agility. When forced to navigate tight spots on a field, the operator will appreciate the minimum turn radius as a decisive benefit!

Bale pick-up

The hydraulic loading arm gently grabs the bale and places it smoothly on the wrapping table, which is slightly tilted forward while the bale is being picked up.

Since it can be adjusted to five different positions, the loading arm can be adapted perfectly to the diameter of the bale. Thanks to the pivoting, ball-mounted reception tube, the bale is never pinched or damaged. It also guarantees that the bale is picked up reliably even in difficult terrain. The bale pick-up also proves to be exceptionally convenient when you need to transport two bales.

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

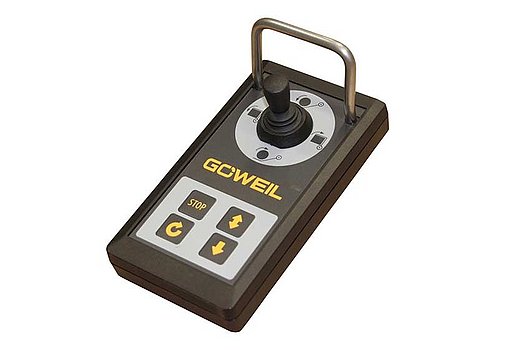

Basic Model

with EU Type-approval

The "bale pick-up" function is performed manually using the electronic joystick. The "wrapping process" and "film cutting" work cycles are performed automatically, while "bale deposit" is started at the push of a button.

Technical data

Weight: | 1,780 kg (3,800 lbs) |

Length: | 3,940 mm (12’ 8”) |

Width: | 2,750 mm (9’) |

Height: | 3,060 mm (10’) |

Bale diameter: | 0.90 – 1.50 m (36” – 60”) (with standard wrapping arm) |

Bale diameter: | 0.90 - 1.35 m (36” – 53”) (height altered to 2,760 mm) |

Oil requirement: | starting at 25 l/min at max. 190 bar |

| Bale weight: | up to 1,800 kg (up to 4,000 lbs) |

Required connections

1 pressure connection and 1 depressurized return for the supply of the wrapper and 1 double-acting control device for the pivoting drawbar |

3-pin power outlet for the electrical supply including direct supply line to the battery (cable cross-section 2x6 mm²) |

7-pin power outlet for the entire lighting system (excluding work lights) |

Additional equipment

Width altered to 2,880 mm (9’ 5”)

Stops the wrapping process if film tears or runs out

(without hydraulic oil)

Including gearbox with pump, return filter, hydraulic oil tank and lower linkage link

Prevents the bale from dropping off the wrapping table in steep terrain

(including additional roller)

For a gentle bale drop onto the field

(including additional roller)

When the wrapping process is complete, the bale is positioned on its right front side with the direction of travel