Fully automatic square bale wrapper

G4020 Q Profi | Square bale wrapper

This trailed machine G4020 Q Profi with twin wrapping arm and bale pick-up is the machine that delivers the highest possible professional performance of any square bale wrapper. Thanks to the PROFI program control, the execution of all cycles is fully automatic. This makes working with this fully automatic square bale wrapper as comfortable as can be.

Highlights

Secure Bale Guiding

The rotating rollers arranged on both sides are connected to each other with tie rods. This produces a controlled force, which in conjuntion with the belt, generates a clamping effect on the bales. The wrapper is able to guide the bale securely even with rectangular bale dimensions. A quick adjustment can adapt the belt length to different bale dimensions.

Basic model

(without hydraulic oil) - WITH EU type-approval

can also be operated in conjunction with tractors without load sensing pump

This ensures that the film will overlap accurately for rectangular bales

The execution of all work cycles is fully automatic

Technical data (basic model)

| eight: | 3,680 kg (8,100 lbs) |

| Length: | 6,410 mm (21’) |

| Width: | 2,410 mm (8’) |

| Height: | 3,710 mm (12’ 2”) (with the lift axle extended) |

| For all bale dimensions: | from 0.80 x 0.80 m to 1.20 x 1.40 m (32” x 32” to 48” x 56”) |

| Single/double bales: | from 1.00 up to 2.00 m |

| Round bale diameter: | 0.90 - 1.60 m (36” - 63”) |

| Oil requirements: | starting at 80 l/min at max. 190 bar |

| Bale weight round / square: | max. 1,800 / 1,500 kg (max. 4,000 / 3,300 lbs) |

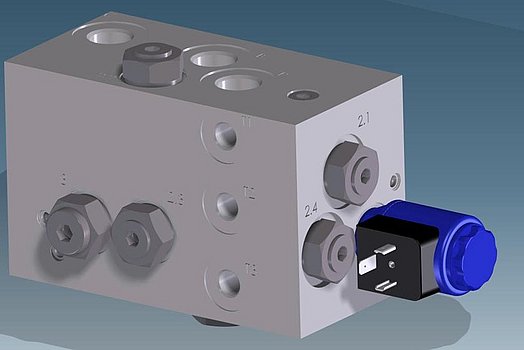

Required connections

1 pressure connection and 1 depressurized return for the supply of the wrapper |

Load Sensing connection (for LS mode) |

3-pin power outlet for the electrical supply including direct supply line to the battery (cable cross-section 2x6 mm²) |

7-pin power outlet for the entire lighting system (excluding work lights) |

Additional equipment

Width altered to 2,545 mm, height altered to 3,770 mm

Required connection: 3-pin socket for electrical supply of the hand-held terminal 12 V / 10 A)

Height-adjustable drawbar with hydraulic support foot for wheel loader operation.

Can be controlled via radio remote control – no PTO drive shaft possible

Only in conjunction with 3-cylinder diesel engine Kubota

Stops the wrapping process if film tears or runs out. Automatically switches to “single-film mode” as soon as one roll runs out. During this process the feed rate is reduced to ensure an overlap of 50 %.

Including gearbox with pump, return filter and 60 l hydraulic oil tank

Not combinable with 3-cylinder diesel engine Kubota

(without hydraulic oil)

17.5 kW diesel engine, water cooled, battery, electric starter, hours counter, return filter and 44 l hydraulic oil tank.

Switches automatically to idle speed after the wrapping process or extended intervals –

Only in conjunction with 3-cylinder diesel engine Kubota

Country-specific additional equipment

WITHOUT EU type-approval

WITHOUT EU type-approval

WITHOUT EU type-approval