3 point linkage round bale wrapper

G3010 | Round bale wrapper

The three-point linkage round bale wrapper is the ideal wrapping machine for customers with smaller bale counts per year. The G3010 impresses with its uncomplicated, efficient operation and can be optionally equipped with a bale pick-up. Find out more about this round bale wrapper's highlights, the design, equipment and more here.

Highlights

Wrapping arm with film pre-stretcher

The wrapping arm comes with a film pre-stretcher for 750 mm film rolls. The patented plastic rollers ensure uniform pre-stretching. This saves film and guarantees tightly wrapped and airtight bales. In addition, the rollers are not temperature sensitive. The quick-change system allows empty rolls to be replaced quickly and easily.

Rotating wrapping arm with stationary wrapping table

It is impossible for the bale to fall off with this system as there are no centrifugal forces acting on it. While the belts ensure continuous rotation of the bale, the two rotating bale guide rollers (optionally up to four) keep the bale in position. This guarantees uniform overlapping of the film. When bale deposit is performed, the wrapping table is tilted to the side and the bale is gently deposited next to the machine.

Film Cutter

The stainless steel cutting knife guarantees clean and precise cutting of the film. At the same time, the film is fixed by the cutting lever. Shortly after the start of the wrapping process, the standard float position ensures easy release of the wrapping film.

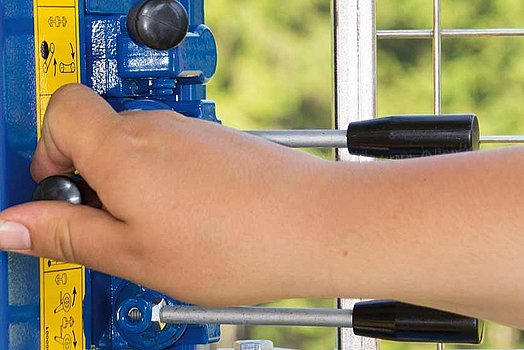

Control unit with hand lever

The control unit and the hand lever are helpful for maintenance and service work. All functions and processes can be performed directly on the machine. This means that the operator can simply leave the handset in the tractor cab.

Drive Types

In the basic model, the wrapper is powered by the towing vehicle. On request, the G3010 wrapper can be equipped with an external drive motor. A choice of PTO or electric drive (4 kW motor) or gasoline engine (8.2 kW) with battery, e-starter as well as hydraulic system.

To activate YouTube please click on the button. By activating embedded videos, data is transmitted to Google. Further information can be found in our privacy policy.

Basic model

The cycles “wrapping process” and “film-holding and cutting” start automatically, while “bale drop” starts at the push of a button

Technical data (basic model)

| Gewicht: | 865 kg |

| Länge: | 2.705 mm |

| Breite: | 1.720 mm |

| Höhe: | 2.670 mm |

| Ballendurchmesser: | 0,90 – 1,60 m |

| Ölbedarf: | ab 20 l/min bei max. 190 bar |

| Ballengewicht | max. 1.800 kg |

Required connections

1 Druckanschluss und 1 druckloser Rücklauf für die Versorgung der Wickelmaschine (entfällt bei Zapfwellenantrieb) |

3-polige Steckdose für die elektrische Versorgung mit direkter Zuleitung zur Batterie (12V/30A) - Leitungsquerschnitt 2x6 mm² |

Additional equipment

The execution of all work cycles is fully automatic.

Only in combination with fully automatic program control PROFI

Required connection: 3-pin power outlet for the electrical supply of the hand-held terminal (12V/10A)

Bale pick-up on the right with or against the direction of travel

Bale deposit on the left (on the right, only possible in bale pick up)

Width altered to 1,825 mm (6’)

Bale weight: up to 1,100kg (2,400 lbs)

Stops the wrapping process if film tears or runs out.

maximum 2 items

Required connection: 7-pin power outlet for the entire lighting system (excluding work lights)

tractor operation still possible

4 kW electric motor, return filter and 30 l hydraulic oil tank, fully assembled

Required connection for electric motor: 400 V / 50 Hz, CEE 16 A, protection class IP55

Including gearbox with pump, slip-on tractor PTO drive shaft, return filter and 30 L hydraulic oil tank

- Tractor operation still possible

- 8.2 kW gasoline engine with battery

- Electric starter

- Return filter

- 30 l hydraulic oil tank